FILLING MACHINE

Showing 97–106 of 106 results

Product tags

Prefilled Syringe Filling Machine ( Speed 1-5000 syringes per hour )

It is a pre-filling machine which is specifically designed for laboratory pre-filling syringes and suitable for filling 1-20ml glass syringe (BD tube).

Sauce Cup Filling Machine ( Speed 30-35 cups per minute )

It uses imported electrical components and pneumatic components, which can operate stably for a long time and reduce shutdown and maintenance time. The material is 304 stainless steel and anodized alumina. It can also operate in harsh environments such as humidity, steam, oil, acid and salt. The fuselage can be washed with water. The automatic cup filling and sealing machine can automatically drop the cup, detect the cup, automatically fill, automatically vacuum, seal the film cup, automatically cover and automatically discharge.

Self-flow Disinfectant Filling Machine(Speed≤2000BPH)

It is a full-automatic direct pressure vacuum filling machine, which integrates light, electricity and gas. It is used to pack disinfectant, pesticide, chemical, water and liquid bottles. Containers of different shapes can be used. It can be matched with capping machine and labeling machine to form a complete production line.

Semi Automatic Syringe Filling Machine ( Speed 10-30 syringes per minute )

We employ the advanced filling system of piston quantification valve in the machine to minimize the filling error.

There is a back suction device in the filling nozzle to make sure no material will be left in the tube. So, the valve and pipeline are convenient for changing and cleaning.

Syringe Filling Machine(Speed 200-1200 Syringes Per Hour)

Manually put the set syringe on the special membrane. Then hang them together on the plate which will put the syringe in order for the next step. The machine will automatically load them in succession into the filling dial which rotates intermittently and completes the filling for once. After that, the filled syringe are inserted into the dial wheel and are transported to the next procedure.

Test Tube Filling Machine(Speed 50 Bottles Per Minute)

It can be used in medicine, daily chemistry, cosmetics and other industries. It can also be used in small glass bottles and plastic bottles, such as electronic liquids, vaccines, essential oils, syrups, etc. This machine body made by stainless steel, and the working process is controlled by touch screen, and the filling volume is adjustable. This machine is suitable for filling capping small bottle of various specifications.

Yogurt Filling Machine ( 600-800 cups per hour )

It uses the piston cylinder to fill the material in the glass. It can be used in food, chemical industry, medicine, cosmetics, pesticides and other industries. It can be used for filling liquids, especially high viscosity materials and foaming liquids, such as yogurt, soy sauce, jam, soy sauce, ketchup, honey, butter, lubricating oil, etc.

ZF12 Automatic Wax Filling Machine(Speed 3000 Bottles Per Hour)

The automatic wax filling machine has revolutionized the bottle sealing process in the brewing industry, providing breweries with an automated solution to streamline operations and add a touch of sophistication to their packaging. By leveraging automation, precision, and versatility, this advanced equipment enables breweries to efficiently apply wax coatings to their bottles, creating a visually striking and memorable experience for consumers.

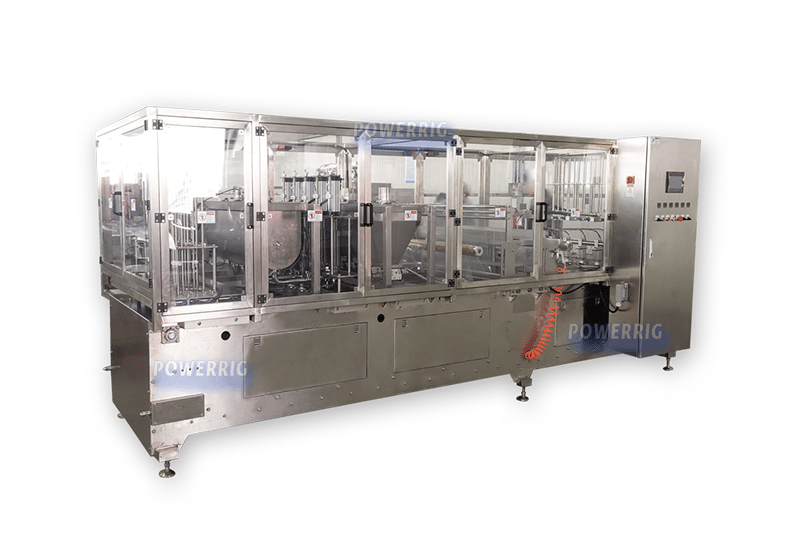

Grease Cartridge Filling Machine(Can Package ZF20 Linear Filling Machine)

A lubricant oil filling machine is a type of equipment used for filling lubricant oils into containers, such as bottles, cans, drums, and other packaging materials.

The machine is designed to automate the filling process, making it faster, more efficient, and accurate than manual filling.

Bearing Grease Filling Machine(Speed 10-30 Bottles Per Minute)

It used in manufacturing and processing industries where large quantities of grease are needed for various applications, such as automotive, aerospace, construction, and marine industries.

Grease filling machines typically use a piston or gear pump to transfer the grease from a bulk container into smaller containers.