Description

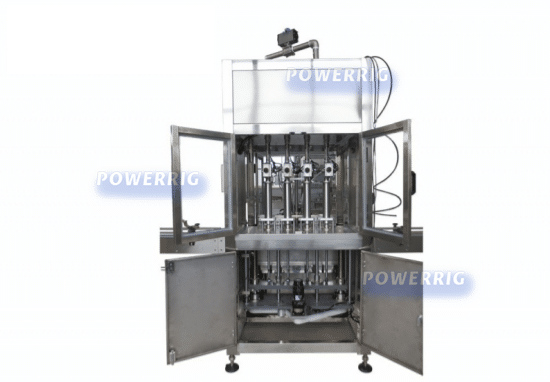

Brief Introduction of Our Lip Gloss Tube Filler Machine:

It can be used to fill lipstick, lipstick, eyeliner, liquid powder and other hot filling products. It can set the filling system and filling volume of the gear pump. The digital input controls the dosing volume and pump speed, with an accuracy of + / – 0.5%. The silicone mold is preheated manually, and the machine is easy to disassemble and clean, which is very convenient.

Four Competitive Edges of Our Lip Gloss Tube Filler Machine:

1.It uses gear pump circulation design, which can be used to evenly fill viscous products.

2.The cover is sealed to prevent volatilization, and the heat conveyor can be added.

3.The machine simplifies the operation and has high safety. It has passed the explosion-proof test and wiring test. It is easy to maintain and can be filled and input accurately.

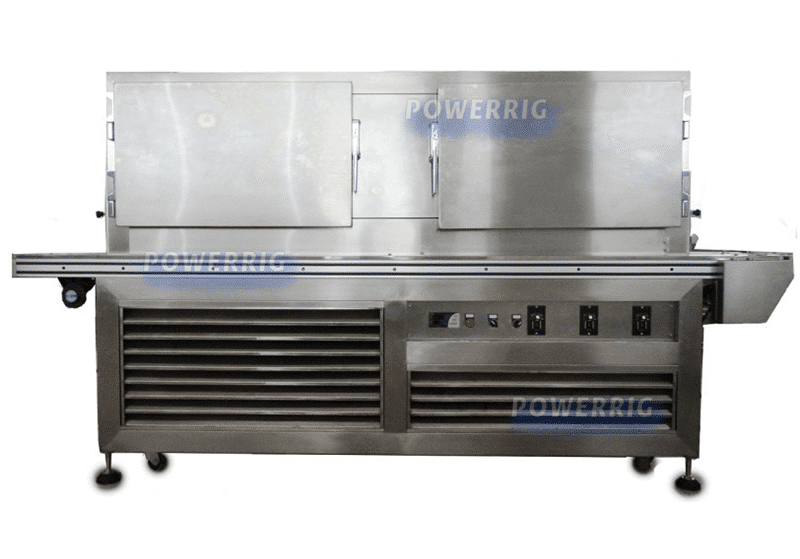

4.Stations 2-4 and two tunnels can be selected. Its frame uses 304 stainless steel, and the temperature is controlled by t.i.c. the conveyor speed and cooling temperature are set according to the product type.

PARAMETER:

CONFIGURATION:

| Technical parameter | |

Filling Nozzle | Single |

Filling Volume | 10cavity or 12cavity molds |

Filling Speed | 1000-1500pcs/hr |

Filling Pump | G ear pump |

Filling Type | Hot filling |

Heating Type | Electric heating |

Volume of Hopper | 25L, two layers |

Air Pressure | 0.6-0.8M ³ /min |

Power | 2.5Kw |

Voltage | 380V/50Hz Depends on customer |

Weight | 150kg |

Dimension | 2500*900*1700MM |

| Configuration list | ||

| Automatic silicone mold lipstick filling machine | ||

Touch screen | Kinco | China |

Switch | Schneider | Germany |

Pneumatic component | SMC | Japanese |

Temperature controller | Autonics | Korea |

PLC | Mitsubishi | Japanese |

Relay | Omron | Japanese |

Conveyor and mixing motor | Zhongda | Taiwan |

| Semi-automatic lipstick releasing machine | ||

Pneumatic component | SMC | Japanese |

Switch | Schneider | Germany |

Relay | Omron | Japanese |