Description

FEATURES:

Brief Introduction of Our Gorilla Bottle Filling Machine:

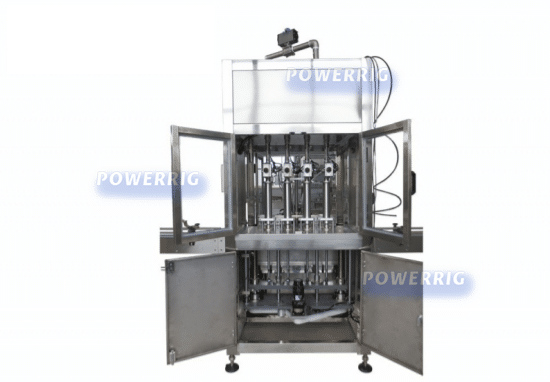

It can be used to fill plastic bottles, glass bottles, jars and all kinds of packaging, widely used in daily chemical, cosmetics, food industry, high viscosity materials, shampoo, hair cream, hand cream dishwashing liquid, it is very effective. The machine is driven by servo motor and driven by double ball screw. It stabilizes the motion of the piston. High precision filling volume stroke, can be effective filling.

Six Competitive Edges of Our Gorilla Bottle Filling Machine:

1.The machine uses PLC programmable control system and can touch screen.

2.Put, fill and bottle the bottles automatically .

3.It can run stably and efficiently.

4.It is easy to operate and integrates light, machinery, electricity and gas.

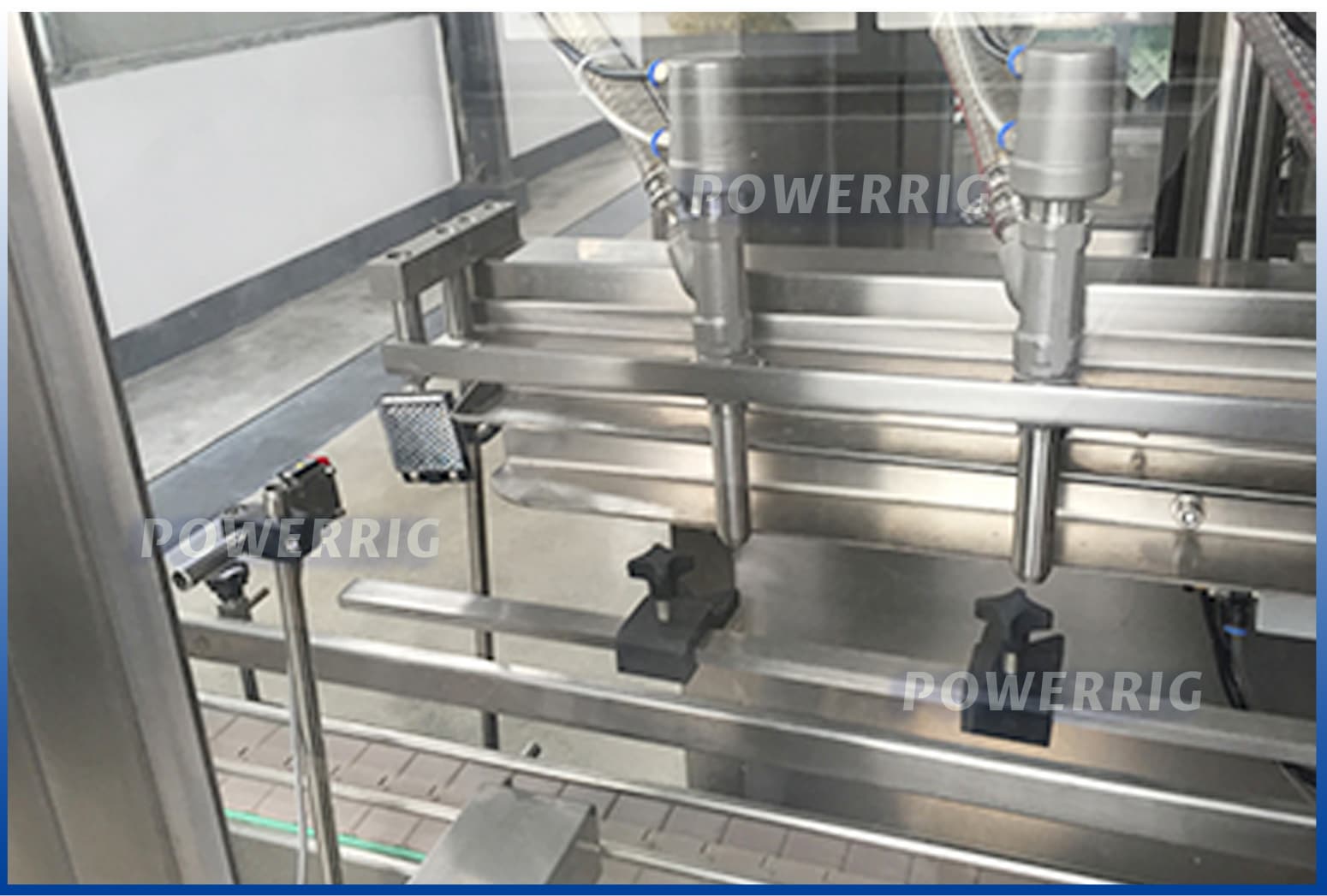

5.Its filling nozzle is double ball screw, can be matched with capping machine, labeling machine to form a production line.

6.The machine is driven by servo motor and twin screw to control the movement of the piston rod, which can be filled stably.

PARAMETER:

CONFIGURATION:

| Filling Nozzle | 4Pieces |

| Filling Volume | 50ml-500ml |

| Filling Speed | ≤2000bottle/hr base on 100ML |

| Filling Form | Piston Pump Type (Servo Control) |

| Accuracy | ≤±3‰ |

| Suitable Bottle Diameter | Ф40mm-Ф200mm |

| Material | Surface: SUS304

Material Contact Part: SUS316 |

| Control | PLC and Touch Screen |

| Air Pressure | 0.55Mpa-0.65Mpa |

| Power | 3Kw |

| Voltage | 380V/50Hz 3phase (Can be customized) |

| Machine Size | 2000*1000*2500MM(L*W*H) |

| Weight | 1500Kg |

| Name | Brand |

| Press-button | Schneider |

| Magnetic Contactor | Schneider |

| Relay | Omron |

| Frequency Transformer | Mitsubishi |

| Motor | JSCC Made in Germany |

| Air Cylinder | Airtac |

| Solenoid Valve | Airtac |

| Speed Reducer | Made in Taiwan |

| Bearing | NSK |

| PLC | Mitsubishi |

| Touch Screen | Mitsubishi |

| Fibre-optical | Autonics |

| Switching Mode Power Supply | NWELL |

| Step Motor | SNAYO Made in Japan |

APPLY: