Description

FEATURES:

Efficient and accurate filling of liquid products is crucial for manufacturers across various industries. The liquid bottle filling machine has emerged as a game-changing solution, revolutionizing the way liquids are filled into bottles. This advanced machinery automates the filling process, delivering exceptional precision, speed, and versatility to meet the diverse needs of liquid product manufacturers.

The liquid bottle filling machine represents a significant technological advancement in liquid product manufacturing, providing a streamlined and automated solution for efficient bottle filling operations. Meticulously engineered, this state-of-the-art equipment seamlessly integrates advanced features to create a versatile filling solution. By combining precision, speed, and reliability, the liquid bottle filling machine plays a crucial role in meeting the evolving demands of liquid product manufacturers.

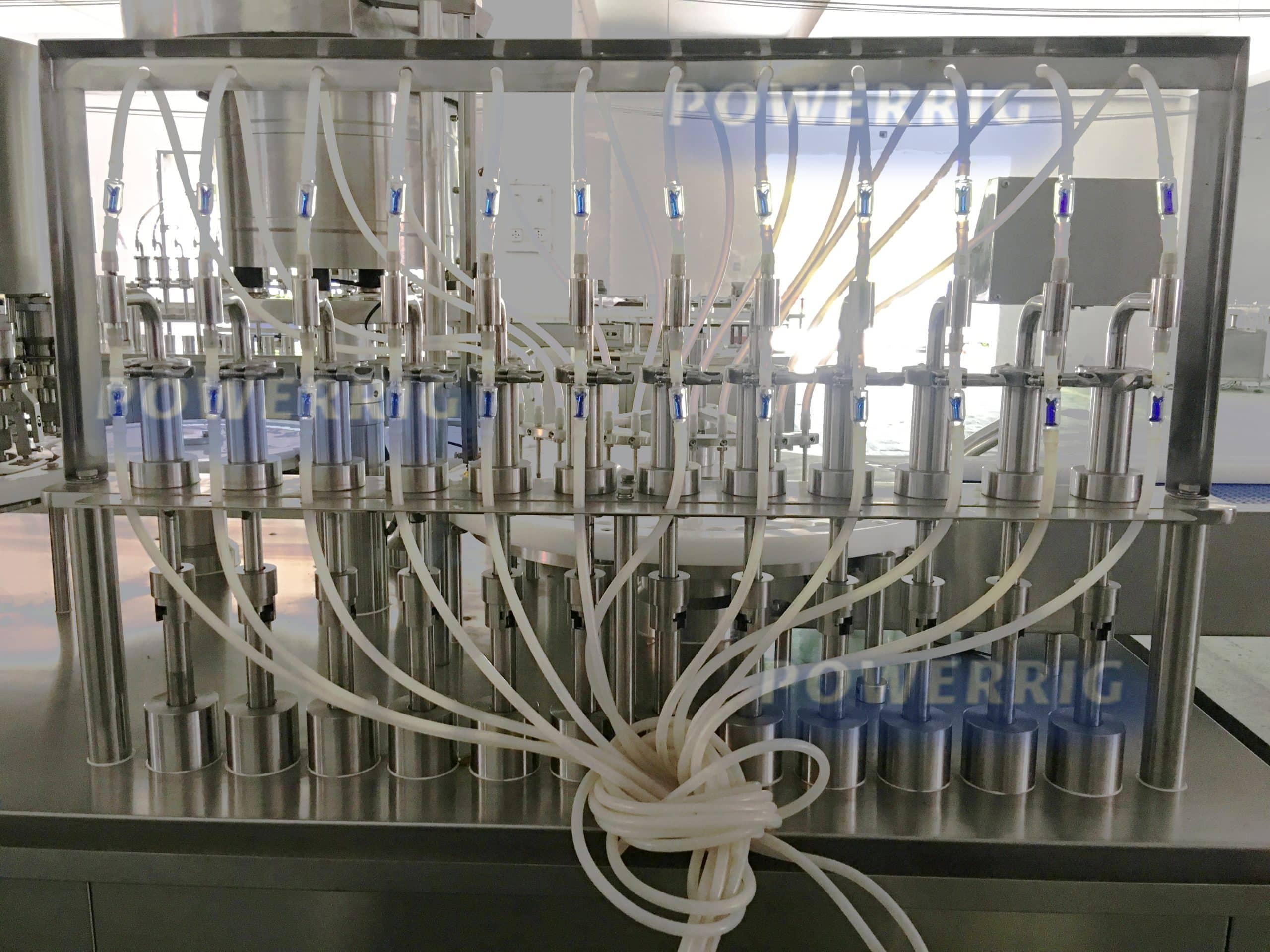

At the core of the liquid bottle filling machine are its advanced mechanisms and components, designed to ensure accurate and consistent filling. This machine streamlines the filling process by automating key functions such as liquid metering, bottle positioning, and filling control. With precise sensors, pumps, and valves, the machine can accurately dispense the desired amount of liquid into each bottle, minimizing product wastage and ensuring consistent fill levels.

One of the key advantages of the liquid bottle filling machine is its versatility in handling various bottle sizes, shapes, and materials. Whether it’s glass bottles, plastic bottles, or other container types, this adaptable equipment can accommodate a wide range of liquid packaging requirements. By embracing the liquid bottle filling machine, manufacturers can efficiently fill their products into different bottle formats, catering to diverse market demands and product specifications.

In addition to precision and versatility, the liquid bottle filling machine enhances operational efficiency. By automating critical processes and eliminating manual labor, this machine significantly reduces filling time, leading to increased productivity. Its reliable design ensures consistent fill levels, minimizing product giveaway and optimizing production output. With its high-speed capabilities, the liquid bottle filling machine is capable of meeting the demands of high-volume production lines, enabling manufacturers to meet customer needs efficiently.

The liquid bottle filling machine has revolutionized the bottle filling process in the liquid product manufacturing industry, providing businesses with a versatile and efficient solution. By leveraging automation and advanced technologies, this equipment enables precise, fast, and reliable filling operations. With its versatility, speed, and accuracy, the liquid bottle filling machine empowers manufacturers to optimize their production processes, reduce waste, and deliver high-quality liquid products to the market. By investing in this technology, businesses can enhance their operational efficiency, meet customer demands, and stay competitive in the dynamic landscape of liquid product manufacturing.

PARAMETER:

| Weight | 1500kg |

| Voltage | 220V 50Hz |

| Filling Volume | 10-20ml |

| Air Supply | 0.6-0.8 Mpa |

| Dimension | 3300*1200*1750mm |

| Motor Power | 3KW |

| Filling Speed | 200 bpm |

| Air Consumption | 1.3m³/h |

APPLY: